Measuring Our Progress

We’ve been working to reduce our impact for generations. Here’s our latest progress.

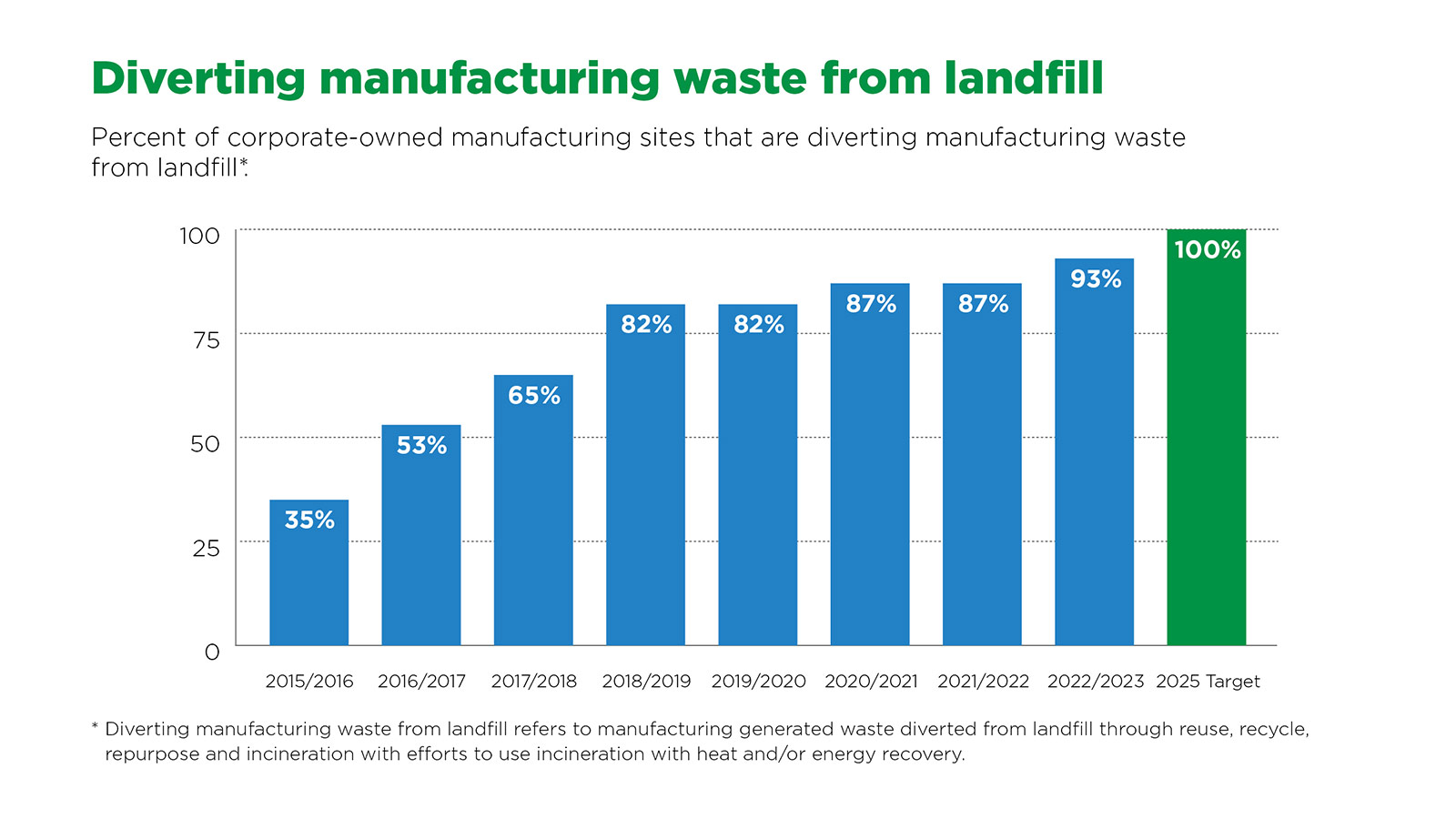

What gets measured gets done. That’s why we’ve been tracking our progress on key environmental goals for decades. On the following pages are charts showing progress on key measures. Among them:

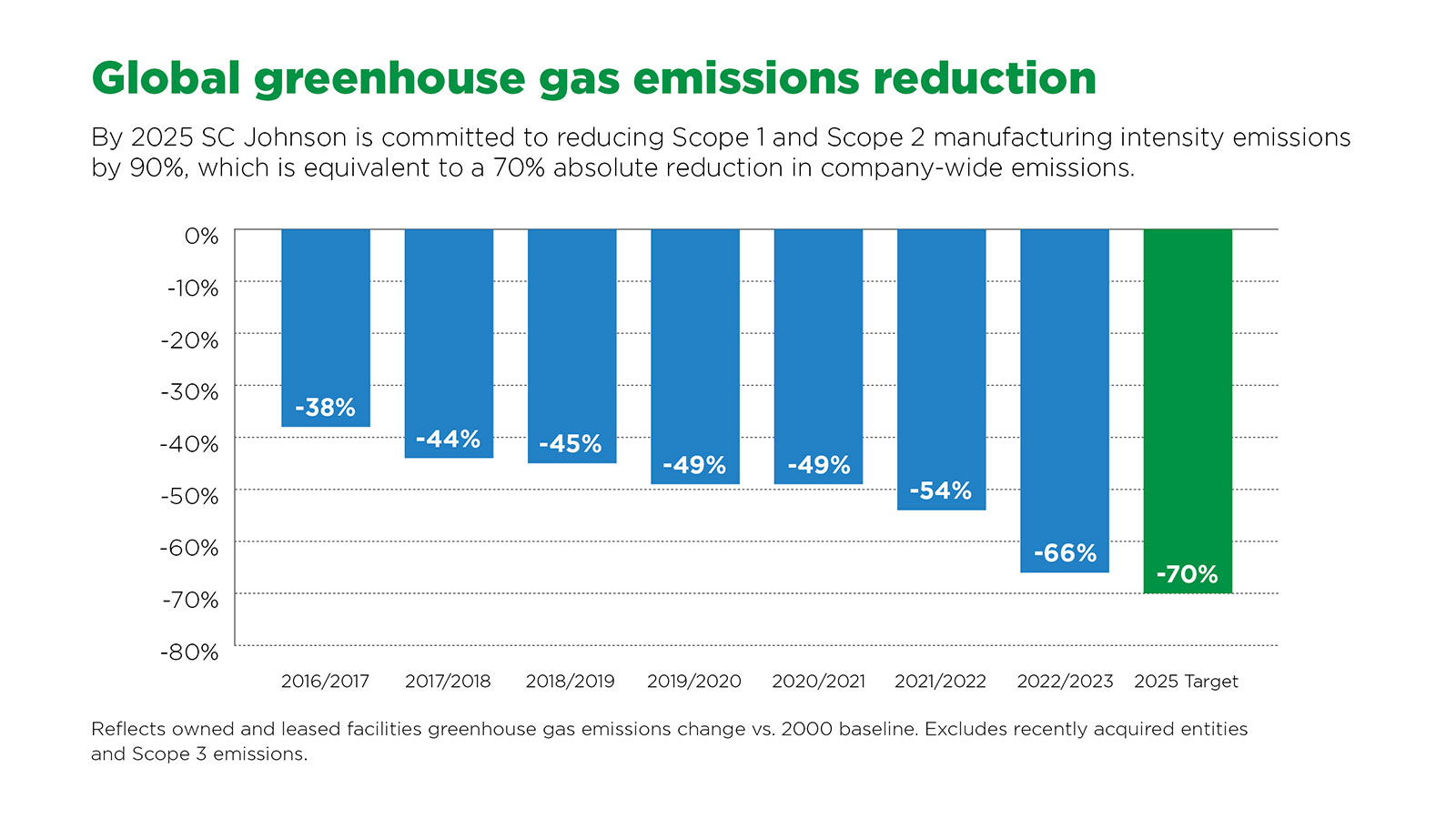

- Our greenhouse gas emissions from manufacturing are down 66% since 2000.

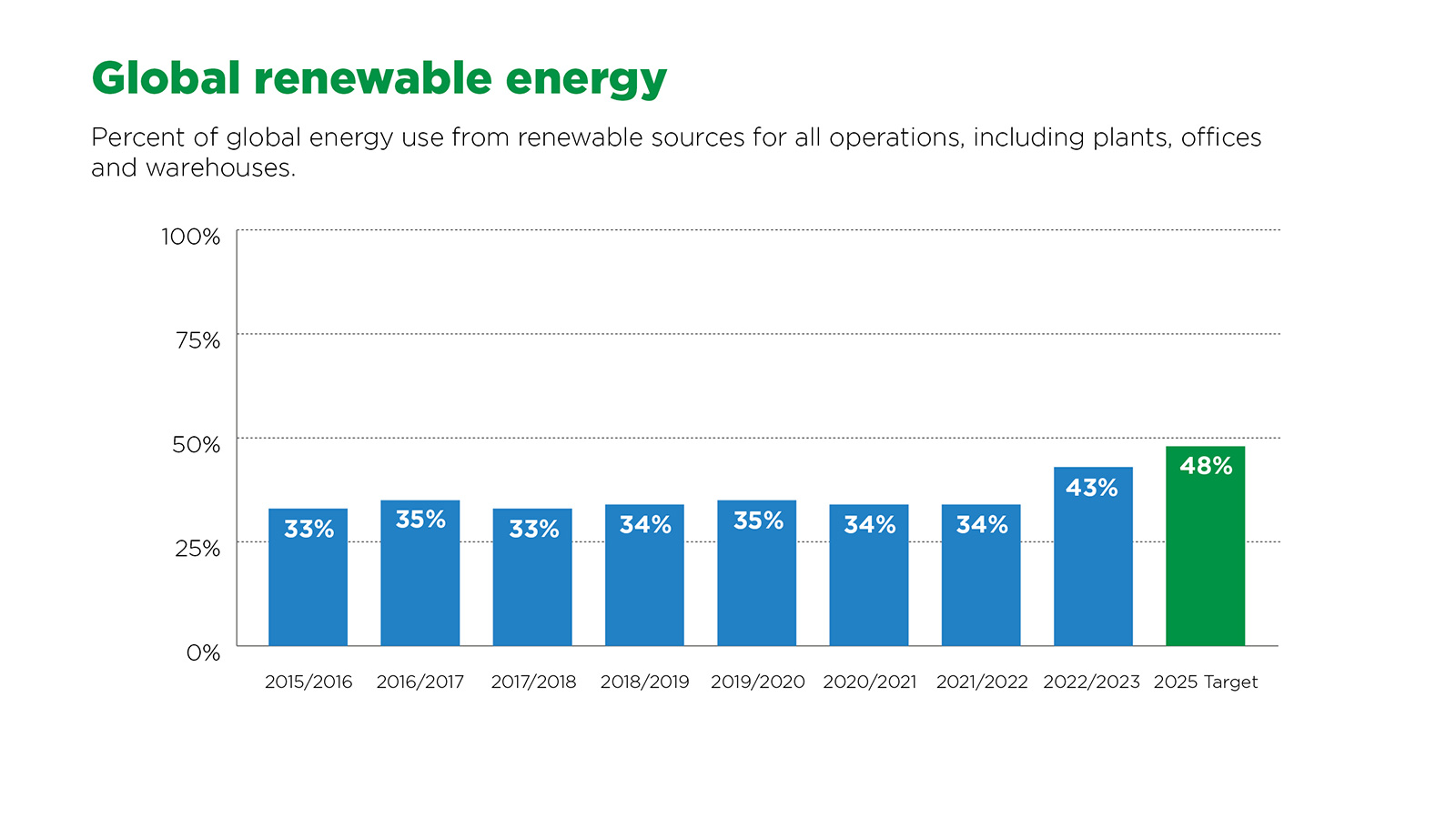

- More than a third of our energy use now comes from renewable sources.

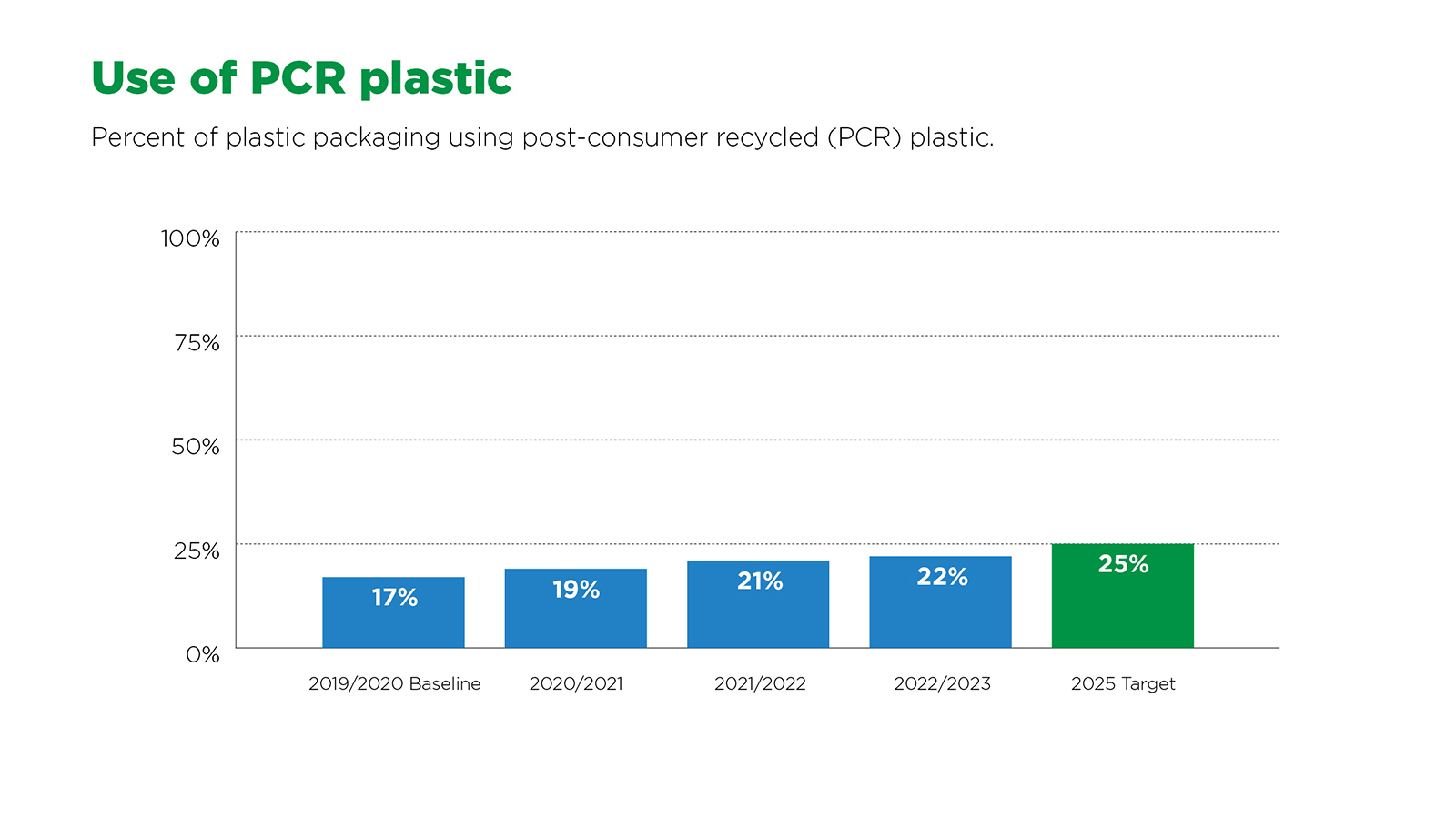

- 22% of our packaging includes post-consumer recycled content.

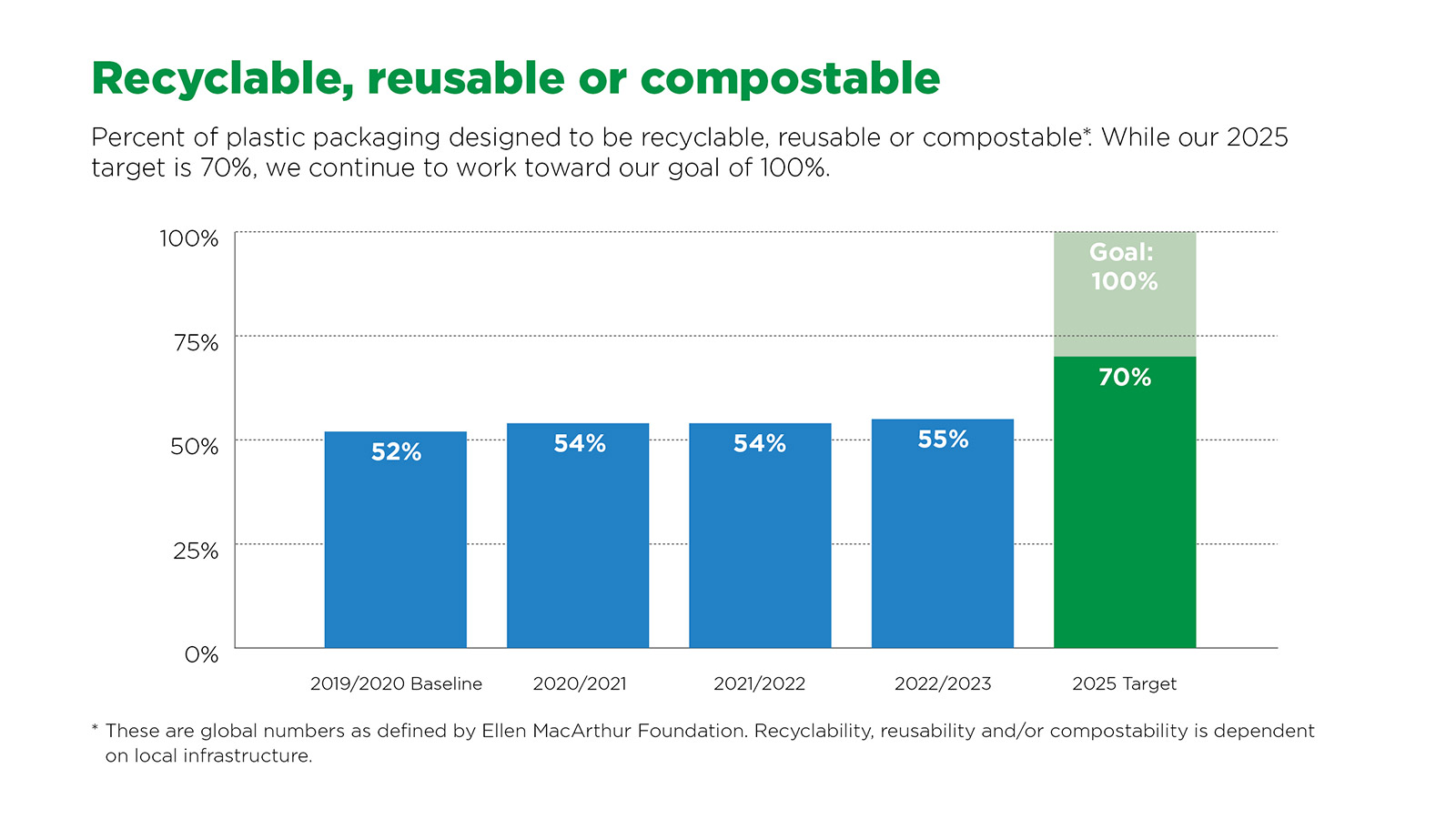

- Over 55% of our packaging is recyclable, reusable or compostable.

A note on our reporting...

Starting with this report, we are expanding our carbon reporting from just our manufacturing facilities to cover all SC Johnson facilities’ Scope 1 and Scope 2 impacts.

Scope 1 emissions are those from owned or controlled sources, for example those generated as we operate our facility. Scope 2 emissions are those associated with energy that’s purchased, for example electricity sourced from a utility.

Reporting all SC Johnson facilities’ Scope 1 and Scope 2 emissions further increases transparency about our operations and their impact. We are sharing our total company-wide carbon footprint.