Federal Dialogue on Extended Producer Responsibility: Fisk Johnson Senate Committee on Environment and Public Works Written Testimony

SC Johnson Chairman and CEO Fisk Johnson Shared Our Company’s Stance on Extended Producer Responsibility Federal Policies with the Senate Committee on Environment and Public Works.

I would like to thank Chairman Carper, Ranking Member Capito and the distinguished members of the committee for the opportunity to testify at this hearing on Extended Producer Responsibility Policies for Consumer Packaging. It is an honor and privilege to be with you today.

This is an incredibly important topic, and I am glad the committee is having this public dialogue.

As a scientist by education, and as a CEO of a large global consumer goods company that is a big user of plastic, I see plastic in two very different ways. On one hand, I see it as one of the most useful, versatile, and cost-effective materials developed in the last century; one that has brought extraordinary benefits to human life and well-being on this planet. I also know how important and integral it has been to our products and packaging.

On the other hand, as a lifelong conservationist, I also have seen how plastic has become one of the more profound emerging global pollutants that is affecting planetary, animal, and human health.

Reconciling those two perspectives is sometimes not so easy. The challenge as I see it – how do we practically, most economically, and least disruptively preserve the benefits that plastic has brought to humanity, while preventing the vast amounts of plastic that end up in landfills or, even worse, end up in the environment where it can affect animal and human health.

SC Johnson has had a long history of leadership on environmental issues. For example, under my father’s leadership, SC Johnson was the first to remove chlorofluorocarbons (CFCs) from all its aerosol products because they might harm the ozone layer. We did it 10 years before the Montreal Protocol required it. For more than 30 years, we have been working on reducing our carbon footprint and greening our chemistry. We were recipients of an EPA Lifetime Atmospheric Achievement Award in 2003, recipient of the Presidential Green Chemistry Award in 2006, among many other environmental awards.

We have specifically been working to address plastic waste for many years. We launched our first 100% recycled plastic bottle 33 years ago – back in 1990. Twelve years ago, we offered our first concentrate – a small packet of concentrated Windex that could be added to an empty Windex bottle with water, enabling consumers to reuse their spray bottles dozens of times. We have continued to take numerous actions and launch many other initiatives to reduce our plastic footprint.

And while we have made significant progress with our company’s overall work on sustainability, for all of our company’s work and ambition on plastic, I can’t raise my hand and say I feel good about the progress we have made.

Few of our product innovations have sold very well. Plastic waste is just not top of mind enough for most people to want to go to the minor inconvenience or pay a few cents more for the refill/re-use options we have offered. And while we have made good strides to reduce plastic in our packaging, cost can be a limiting factor. For example, incorporating recycled plastic in our products can put us at a competitive disadvantage when the cost of recycled plastic is significantly higher than virgin plastic. We will be at 25% PCR in our packaging globally by next year.

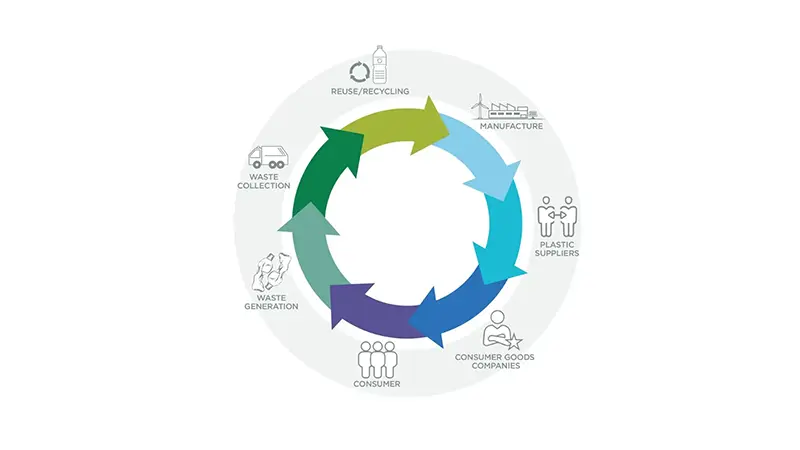

The fact is that voluntary actions only can go so far. It is incredibly difficult for an individual business, or even businesses as a whole, to make unilateral progress on the plastic waste issue. It takes everyone in the plastic ecosystem (from plastic manufacturers, packaged goods companies, retailers, recyclers, waste haulers, to individual users of plastic products), to work collectively together in order to make significant progress and capture economies of scale.

If one or more of the packaging value chain stakeholders in the circular economy cycle is not contributing… the whole thing loses effectiveness.

In our view, the only practical way to get every stakeholder in the plastic ecosystem working collectively together and drive scale is a government regulatory framework. All companies of sufficient size in the ecosystem have to be a part of it for it to work and to drive the right economics and change.

There are excellent examples of where regulation has worked, and recycling rates are high. British Columbia, which has had EPR in place for more than 10 years, is a good model, with one of the highest recovery rates and recycling rates in the world.

I would like to share 5 reasons why we believe stronger regulation is warranted. And then come back to what we feel is the best kind of regulation and what works for the practical implementation of it.

- Americans want stronger plastic regulation: Based on a recent survey we conducted, 79% of Americans today believe the government should be leading the way in dealing with plastic waste. Only 11% of plastic in the U.S. that could be recycled is recycled. And yet, it’s not because Americans aren’t putting the plastic in their bins, too much of what people try to recycle ends up in landfills.

- Without federal regulation a complex web of state regulations is emerging which will drive significant cost and dysfunction: Today several states (California, Oregon, Washington, Colorado, Maine) have already passed EPR regulation, and nearly a dozen states are in various stages of considering legislation. We’re already seeing different states offering conflicting definitions of what constitutes “packaging,” who counts as a “producer,” and what it means to be “recyclable.” They have different fee structures, different targets, and varying timetables. While well-meaning and good progress – assuming more and more states do this, we will end up with a spider web of differing plastic regulations across the U.S. that will inevitably drive a massive increase in complexity and cost and pose a significant compliance burden for 50-state marketers like SC Johnson. We need a federal solution that is consistent country-wide, and provides the scale and efficiencies needed to truly tackle this issue.

- Regulation is necessary to get everyone in the plastic ecosystem working effectively together and at scale: Voluntary actions don’t work very well. Business cannot solve this problem alone. It takes all the stakeholders in the plastic ecosystem working together to make all parts of the recycling ecosystem work effectively together and to drive economies of scale. If one part the recycling loop is not effectively operating, the whole system doesn’t work efficiently.

- Continuing to accumulate landfill waste is unsustainable: A federal EPR framework can help address the pressing issue of landfill overcrowding, which is becoming increasingly unsustainable. The U.S. produces over 292 million tons of municipal solid waste annually. By 2030, it's estimated that U.S. landfills could reach their maximum capacity. EPR incentivizes packaged goods companies to design products with better end-of-life management, thus reducing the amount of waste sent to landfills.

- The environmental impact of virgin plastic is greater than recycled plastic: EPR can significantly reduce the environmental impact of the reliance on virgin plastic, such as its carbon impact, as well as the environmental issues associated with the extraction of oil and production processes.

Time is of the essence in establishing a federal EPR framework.

There are two primary reasons why we believe the sooner regulation is implemented the better.

- It’s vitally important to get ahead of emerging state regulations before they become too overlapping and drive complexity, significant cost and dysfunction.

- The sooner regulation is enacted, clear goals are set, and the more time that is given to achieve those goals, the better. This will allow a smoother transition towards sustainable plastic management and will best minimize disruptions to businesses, the economy, and consumers. Time allows for product innovation (in recyclability, recycled content, re-use/refill). It allows for innovations that eliminate the use of plastic and moves to alternate materials where practical. It allows for improvement of recycling technologies. It allows for consumer education programs and behavior change. The sooner clear goals are set for industry the better. Waiting to enact legislation until it becomes more of a crisis and then expecting significant progress in short order can only create significant disruption.

There are excellent examples of where regulation has worked, and recycling rates are high. As mentioned, the regulatory framework in British Columbia is a very effective program where packaged goods companies and brand owners like SC Johnson assume financial and operational responsibility for collecting, sorting, and recycling of their packaging through the complete recycling loop. There are target collection and recycling rates; incentives to continuously improve environmental outcomes, product makers cover a significant portion of the recycling service's cost; and a governance structure in which the government retains an oversight role. It's a sound system and framework.

In the U.S., Colorado's new EPR program for packaging and paper products, which has many of the same elements as British Columbia's, is also a good working framework that is largely consistent with the design principles for optimal EPR developed by the Consumer Goods Forum, which SC Johnson helped write and has endorsed.

One important element that is not part of current EPR frameworks but should be considered are ways that help promote re-use and refill opportunities. Refill or re-use options have significant environmental benefit in that they keep plastic out of the recycling loop and waste stream. It can also help make alternatives to plastic such as aluminum or glass more practical in certain applications. An example of re-use/refill that I mentioned is the concentrates to use to refill our Windex bottles. Another is refill stations where you can bring in your laundry detergent bottle and refill it in store. Some European countries are putting refill/re-use incentives into their regulatory structure. Today, one of our SCJ brands, Ecover, has 700 retail refill stations in the UK, Germany, and Belgium. Though it should be noted that this effort has had some success as Europeans tend to be much more attuned to the necessity of eliminating plastic waste.

When we talk about plastics, another looming issue, while not core to EPR, is microplastics. The presence of microplastics, and even nanoplastics, in food, water and within the human body is a growing problem with not a lot of known consequences. These studies are going to continue to come, and with that will come an increase in public concern. Whether as part of EPR, or in other ways, it’s an issue that we’re going to have to come to terms with.

In closing, I’d like to reiterate that I see EPR, when done right, as a pragmatic practical solution that can be implemented with the least disruption to the economy and consumers.

By holding packaged goods companies accountable for managing the end-of-life of their products, EPR encourages innovation and investment in alternatives. This approach allows changes to occur where opportunities for improvement are most significant, fostering the adoption of more efficient and less expensive substitutes for plastics. This is especially the case if stakeholders in the packaging value chain are given time to adapt. Sudden changes to supply or stretch goals with short time frames can alternatively be quite disruptive. It also avoids the risk of unintended consequences such as shortages or increased costs for essential plastic products, like those used in medical settings.

Again, thank you for holding this hearing and beginning a federal dialogue on EPR. It is critically important. I appreciate having the opportunity to add my voice and the efforts of SC Johnson to the conversation and eventual legislation on this critically important topic. We want to continue to play a helpful role in getting to a pragmatic solution.